Room Integrity Testing

The ability for the gaseous agent to be retained in the protected room for an extended period of time is critical to the performance of any total flooding clean agent fire extinguishing system. NFPA 2001, Standard on Clean Agent Fire Extinguishing Systems, requires that a minimum concentration of 85% of the adjusted minimum design concentration be held at the highest level of combustibles for a minimum period of 10 minutes. Those installing these systems are required to perform a Room Integrity Fan Test to assure the protected room will hold the agent for the required period of time.

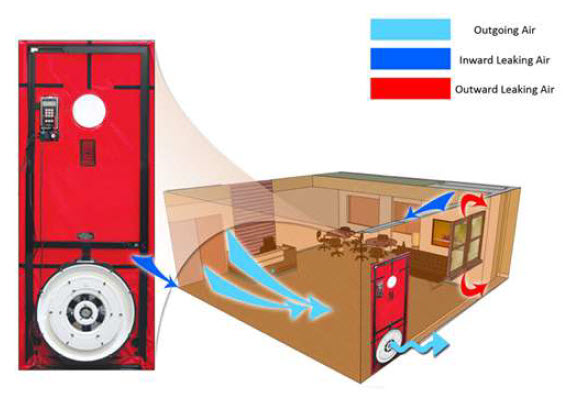

A Room Integrity Fan Test, also known as a Door Fan Test, is simply a way to measure the leakage of an enclosure. A large fan is temporarily installed in the doorway of the room to be tested, with the fan blowing into the room (pressurizing the room). The fan speed is adjusted to obtain flow pressure equivalent to the pressure exerted during a fire suppression system discharge. The fan is then reversed on the door to draw air from the room (depressurizing the room). The airflow and pressure readings obtained are entered into a computer program designed to calculate the equivalent leakage area (ELA) for the room. When a room has a suspended (drop) ceiling, then the below ceiling leakage area (BCLA) is calculated as one-half the total ELA and is used in the calculations for retention time.

Given that most gaseous chemical agents used for fire suppression are heavier than air, the agent will begin to leak out of any lower level penetrations left unsealed. The rate at which the agent leaks is directly proportional to the amount of leakage at higher elevations of the room. As agent leaks out, fresh air replaces it from above. The point where fresh air above meets the concentration air mixture is called the descending interface.

Because of its nature, a Door Fan Test will always calculate the worse case leakage for the room. It draws air through leaks in the room and under the floor as well as above the suspended ceiling to predict the descending interface of the suppression agent. The length of time it takes for the descending interface to reach the minimum protected height identifies the concentration hold time.

Importance of Room Construction

Most rooms housing mission critical equipment are constructed with the perimeter walls extending from “slab to slab” in a manner that creates a fire rated barrier around the room. Because of their construction, these rooms will have fewer leaks and have a much greater chance of passing a standard Room Integrity Fan Test. However, it is possible to achieve a successful test in a room where the perimeter walls do not extend from “slab to slab” but instead extend only to above the suspended ceiling. Rooms like this with large overhead leaks will not pass a standard door fan test but can be successfully tested by other means. Experience has shown that enclosures of this type are capable of retaining clean agent for a prolonged period of time.

When preparing a room to retain a gaseous fire suppression agent, the walls and slab must be inspected for penetrations and leakage points. All areas of concern must be properly sealed with fire retardant materials and doors fitted with pressure seals around the jams and threshold.

Testing by Technical Judgment

In some circumstances it is necessary to gain the approval of the local Authority Having Jurisdiction to waive the quantitative results of a standard door fan test and instead conduct a detailed witnessed leak inspection. This alternate testing process is described in NFPA 2001 Annex C.1.2.2 (5) in a section titled Technical Judgment.

Using the door fan and a smoke pencil, all floor and walls are closely examined for leaks. If the smoke moves radically around potential leakage points, one could assume air is passing through the leak, and therefore improperly sealed. However, if the smoke behaves in an acquiescent manner around potential leakage points, one could assume the room is sealed correctly and therefore passes the test by “technical judgment” of the Authority Having Jurisdiction.

Building Air Tightness Testing Systems

Description

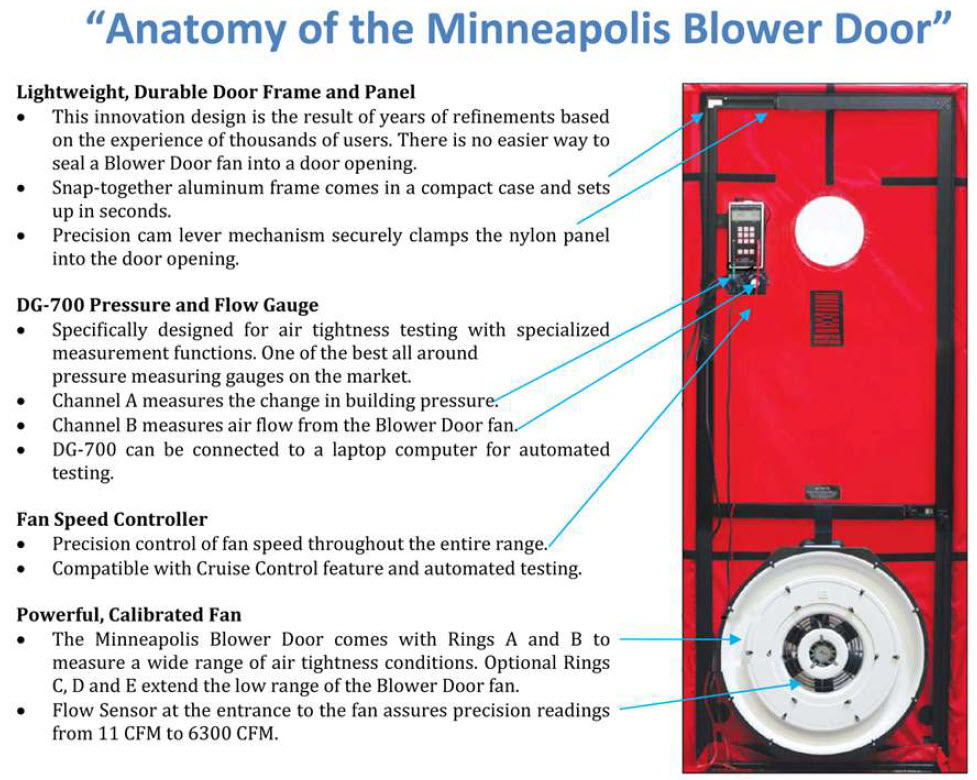

Blower Door tests are used to measure the air tightness level of building envelopes, diagnose and demonstrate air leakage problems, estimate efficiency losses from building air leakage, and certify construction integrity.

Automated Testing Options

Automated testing provides computerized control of the Blower Door fan and automated capture of the building pressure and fan flow measurements. This feature reduces operator error, ensures that tests are conducted the same way every time, and improves test accuracy in windy weather. Automated testing even includes a "Cruise Control" feature for maintaining a constant building pressure during diagnostics or air sealing. In addition to a use supplied laptop computer, automated testing requires:

- DG-700 Gauge (Standard equipment) or an APT Data Acquisition Box

- TECTITE Software

- Cabling to connect the Blower Door System to your laptop computer

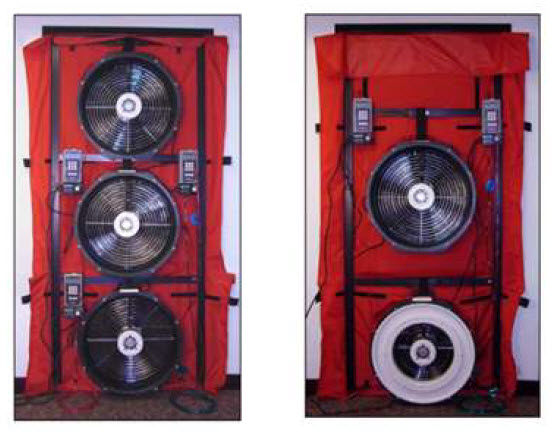

Multi-fan Blower Door System

Blower Door Accessories

TECTITE Airtightness Test Analysis Software

- Calculates building airtightness test results including leakage areas, ACH50, CFM50, building leakage curve, estimated natural and design infiltration rates, and the cost of air leakage.

- On-line help screens make TECTITE extremely user friendly.

- Compatible with both manual Blower Door tests and automated tests using a DG-700 or APT System.

- Calculation procedures and reports are done in accordance with CGSB-149. 10-M86.

- Calculates mechanical ventilation requirements in accordance with ASHRAE 62.2.

- Easy to use data entry screens, file storage, and file retrieval features.

- Choice of report formats including an easy to read homeowner report or a detailed technical report.